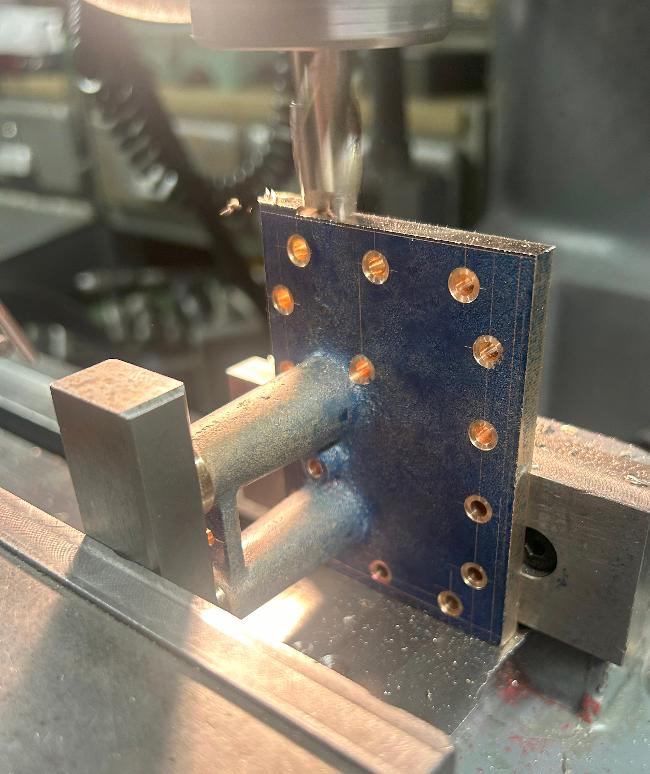

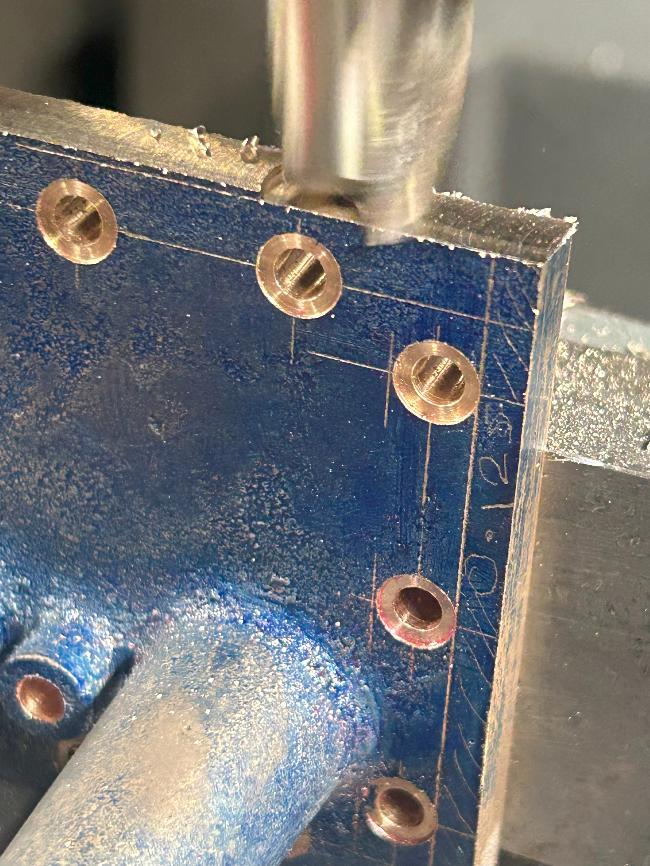

The Foden safety valve casting, although looks like the drawing, once finished, dimensionally this isn't the case. The distance between the stack centres is dimensioned as 1 1/8" on the drawing, but the actual distance to be correct and central on the casting needed to be 1 3/16". This had a knock on effect. Firstly the bolt holes had to be adjusted to enable a 4BA nut to fit at the bottom of the stacks. The stacks were set 1/8" and 1/32" off true dimensions. Secondly the cover plate was machined with minimum clean up to accommodate these adjustments . Even with these adjustments a 4BA one size smaller hexagon nut will have to be used.

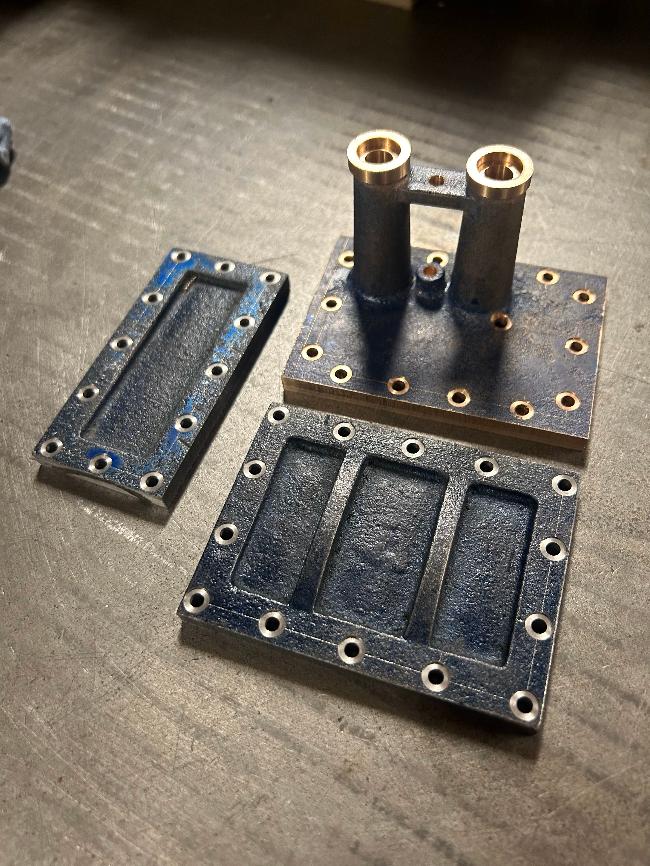

Photo below shows the additional marking out to get everything to fit within the casting.

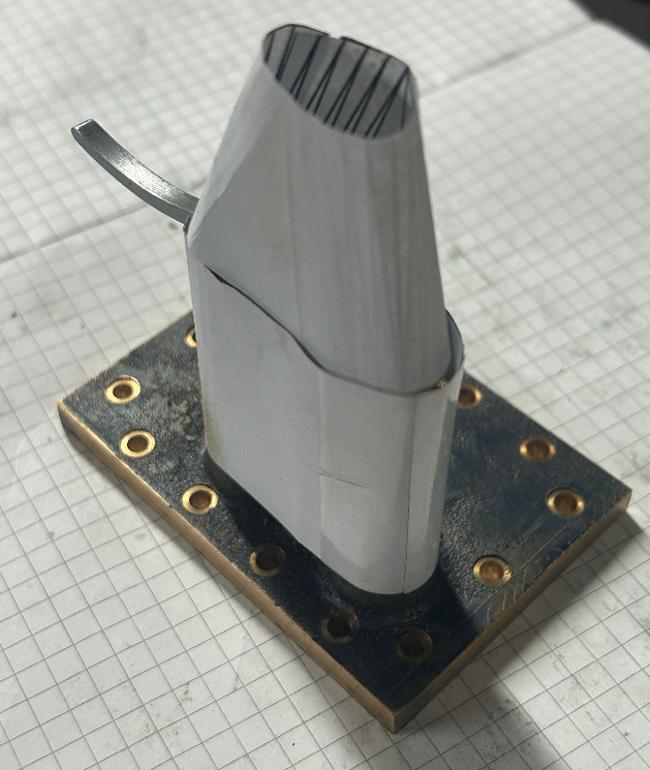

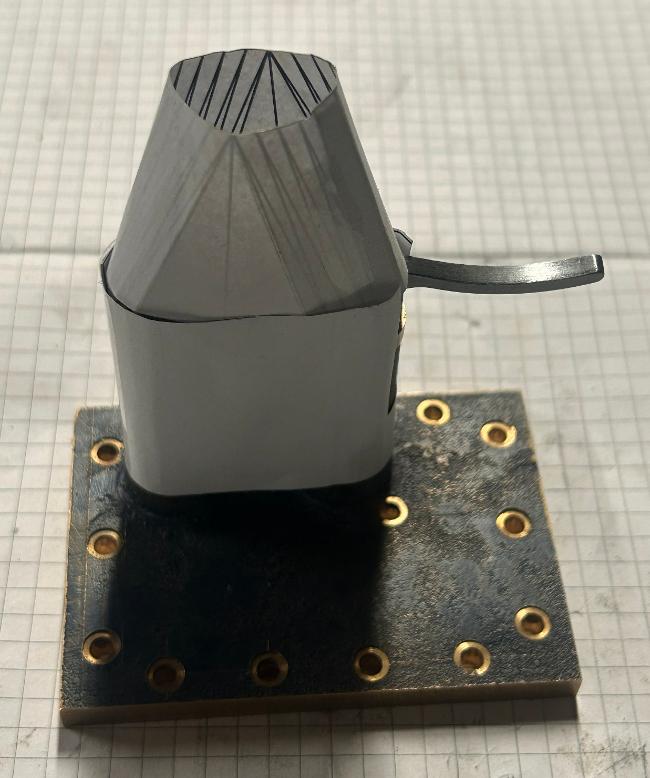

Checking fit of safety valve cover using a folded paper template. Which can then be used to mark and cutout the brass sheet to manufacture the cover.