The casting were first aligned in a 4 jaw chuck and set up to run as true as possible to the main trunk diameter with a scribing block. Which enabled both castings to have a datum diameter turned on the cylinder block end of the trunk guide. This was for two reasons firstly so the casting could be clamped in a vee block true to the axis of the casting. Secondly as a reference point to obtain the centre line of the casting.

The vee blocks allow the casting to be marked out in all plains with out removing the casting from it, as the horse shoe clamp is inboard of the vee block

Scribing trunk guide centreline with vee block on its side

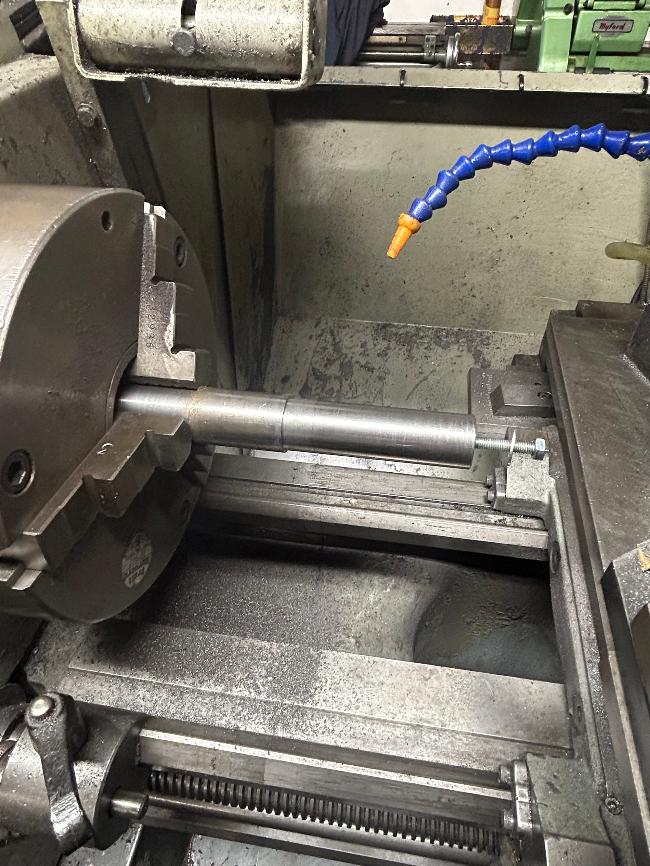

Modified mandrel, taper removed and threaded so casting can be clamped with studding and nut

2BA and 5BA Spot faces completed with homemade reverse spot face tools